If you’re trying to remove tarnish from your jewelry, try Flitz Brass and Copper Remover. Whichever cause may be, non-natural makeup is the enemy of silver, copper, and brass jewelry. It could be a result of your earrings resting on the side of your face or makeup touching and coating your necklace when you remove it. Remember that there are certain chemicals found in modern makeup that can cause your jewelry to tarnish as well. It breaks the outer portion of the metal, making it quite a bit weaker than it normally would. When the metal surface, such as a ring or necklace, is rubbed against another surface, it starts to chip away. Metallic abrasion is a common cause of tarnish as well. When they interact with one another, the result is a slight deterioration paired with a strong color adjustment. Oxygen and sulfur dioxide are the two primary non-metal compounds that cause tarnish on metals. The key takeaway from this section should be that rust is never a good thing, but the others are great when controlled. You might be chasing the aesthetic or trying to get rid of it, but they’re all unique in their own ways.

This suggestion, along with the other four, are the exact reasons that nobody intentionally rusts a surface.Īs you can see, there are several differences between these three substances. Patina and tarnish don’t cause any harm unless you’re using chemical sprays to artificially change the color.

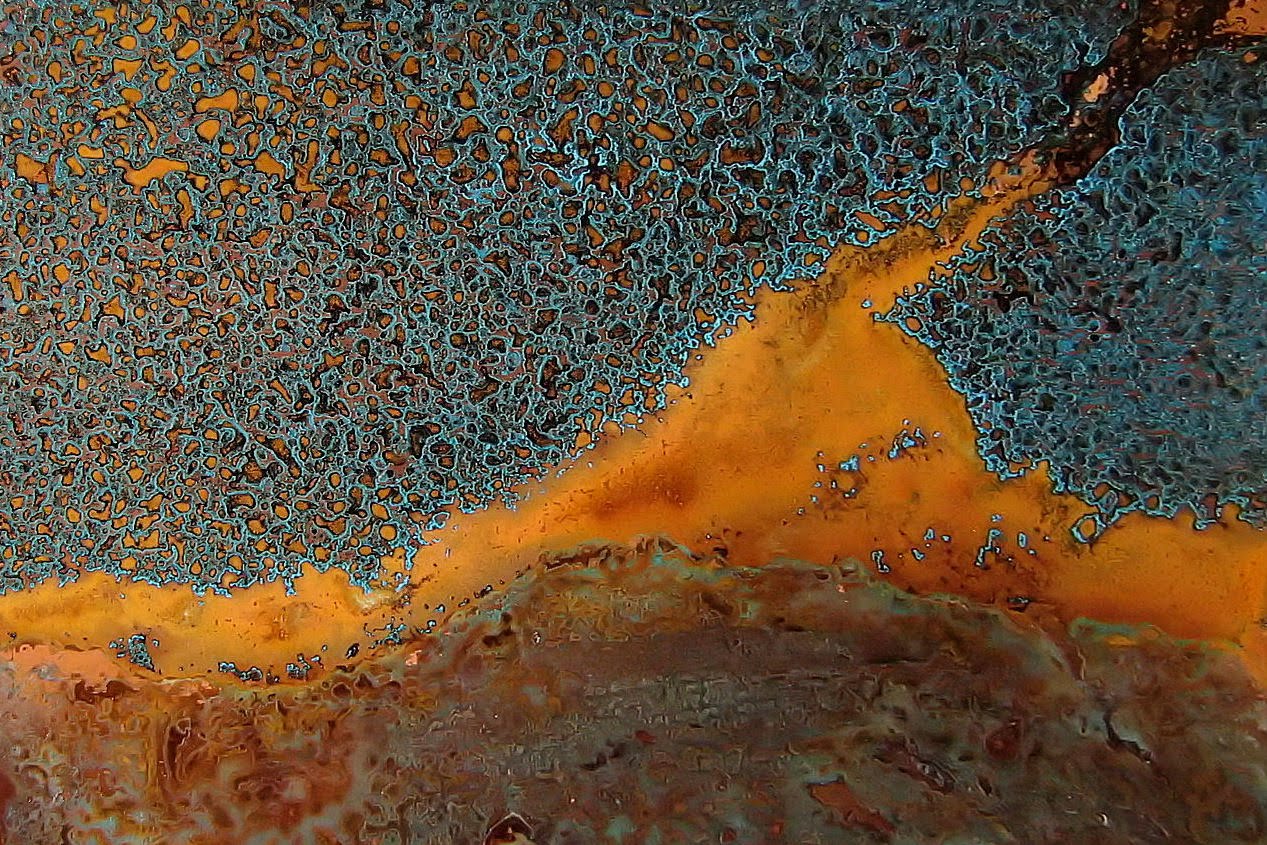

On the other hand, rust shows up as a red-orange color that’s not quite as good looking. They’re often visually appealing to people who prefer vintage appearances. Tarnish and patina are usually grey, black, or green.They look very similar at times, but the differences can’t be mistaken. Both processes (including patina as well) can’t occur on most solid iron surfaces. Tarnish happens to copper, brass, aluminum, silver, and a few other metals.They’re much more likely to happen in outdoor environments, but rust can occur in any environment that fits the aforementioned requirements. Another difference between the three processes is that rust is created by moisture and oxygen, whereas tarnish and patina are made by oxygen exposure alone.Tarnish and patina aren’t too dangerous at all since they’re simply a discoloration. Rust starts to chip away and corrode the metal surface, creating porous cracks and hazardous, sharp edges. Rust is caused by deterioration, whereas tarnish and patina are made through oxidation.It’s also quite a bit more dangerous in most situations.īelow, you’ll find the five main reasons that make rust, tarnish, and patina so different from one another: Rust is the outlier of the group since it’s formed through a separate process and with different types of metal. Patina is simply a form of tarnish, which makes it the same thing in a sense. How Is Rust Different From Tarnish and Patina?Īs mentioned above, tarnish, and patina are very similar. How Is Rust Different From Tarnish and Patina?.Stainless Black Patina is made to create a black patina finish on stainless steel. Rust will occur after 12 hours if a clear sealer is not applied.īlack Magic will darken bonded bronze, brass, and copper castings as well as Sculpt Nouveau's Metal Coatings to an orange-black color.īlack Magic creates a beautiful brown-black patina on cleaned bronze, brass, and copper. Water rinsing is a good neutralizer and will not cause rust.

Rust will not occur immediately as with other darkening patinas.

#CHEMICAL PATINA COPPER SERIES#

In his ongoing series of free video lessons, Ron Young demonstrates the Slate Black Patina application process on bronze cold cast resin.īlack Magic Patina instantly creates a beautiful rich black patina on clean iron & steel. When dry, protect the finish with multiple coats of a clear sealer. Additional patinas can be layered over a Slate Black base. Slate Black Patina may be diluted up to 50% with distilled water depending on the desired strength of finish. Depending on the application method chosen, the results will range from a uniform solid color to a layered textured appearance. Slate Black may be applied as a spray or in an immersion process. On iron, steel, and nonferrous metals, Slate Black will form a black patina when applied cold.īefore applying this patina, sandblasting or sanding is required to clean the surface of oil, oxides, and residues. Slate Black Patina is a versatile and unique finish for use on iron, steel, stainless steel, aluminum, bronze, brass, or copper.Īpplied hot, Slate Black will create a deep brown patina on aluminum and a red-green finish on stainless steel.

0 kommentar(er)

0 kommentar(er)